All About Stretch Wrapper Repair Work: Why Timely Upkeep Is Crucial for Your Service

Timely maintenance and repair service of stretch wrappers are essential for organization performance. Disregarding these makers can lead to different functional challenges, including item damages and increased expenses. Normal examinations can prevent small concerns from intensifying right into major failings. Recognizing the relevance of upkeep is vital for guaranteeing regular wrapping quality. Nonetheless, many companies forget this important element. What are the certain signs that indicate a stretch wrapper needs focus?

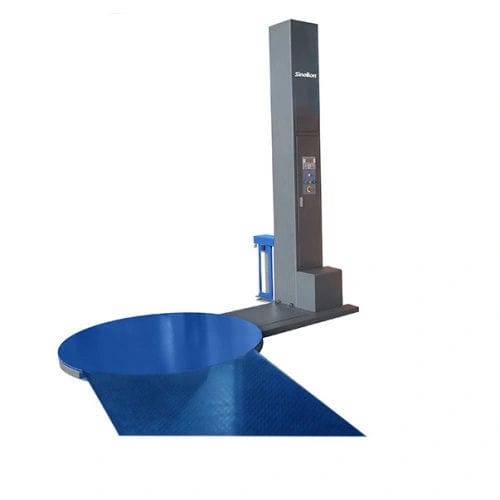

The Relevance of Stretch Wrapper Upkeep

Keeping a stretch wrapper is crucial for ensuring excellent performance and durability. Normal upkeep assists to avoid unexpected malfunctions, which can lead to expensive downtime and manufacturing hold-ups. A well-maintained stretch wrapper runs efficiently, making certain that products are safely covered and prepared for transport.Routine checks on components such as the film carriage, roller assembly, and sensors are significant; they aid determine damage before it escalates into substantial issues. Cleansing the equipment, oiling moving components, and readjusting stress settings can improve performance and expand the tools's lifespan.Moreover, adherence to an upkeep timetable fosters a more secure working atmosphere by lessening the danger of crashes brought on by malfunctioning equipment. Investing time and sources in correct upkeep not just safeguards the stretch wrapper but also adds positively to overall operational effectiveness and cost-effectiveness. Eventually, a positive upkeep technique is vital for sustaining efficiency in any company counting on stretch wrapping modern technology.

Usual Issues Ran Into With Stretch Wrappers

Stretch wrappers can experience a range of usual problems that impact their performance and dependability. One widespread problem is irregular stress in the stretch film, which can cause improperly secured tons. This inconsistency might stem from damaged tension controls or worn-out components. In enhancement, mechanical failings, such as malfunctioning motors or faulty sensors, can result in functional hold-ups and enhanced downtime.Another common problem is film damage, usually triggered by inaccurate stretch setups or substandard quality movie, which can disrupt the covering process. Imbalance of the load can likewise happen, leading to unequal covers that compromise security. Additionally, accumulation of debris or dirt in the equipment can hinder its performance, requiring regular cleansing and maintenance. Electric problems, like wiring faults, may arise, possibly creating system failings. Dealing with these usual problems without delay is crucial for maintaining excellent performance and decreasing disruptions in packaging operations.

Indicators That Your Stretch Wrapper Needs Fixing

Recognizing the signs that a stretch wrapper calls for repair is necessary for keeping operational effectiveness. Unusual noise patterns, inconsistent film tension, and regular film breakage are crucial indicators that something might be amiss - stretch wrapper repair. Addressing these concerns quickly can prevent a lot more considerable problems down the line

Unusual Noise Patterns

How can unusual noise patterns signal prospective concerns with a stretch wrapper? These sounds often suggest underlying mechanical problems that call for instant attention. Grinding or squeaking audios might recommend misaligned components or used bearings. Furthermore, an abrupt boost in volume can aim to loose parts or falling short motors, which could result in functional failings. If a stretch wrapper emits irregular clattering or banging sounds, it may show that interior parts are entering into contact with each other inappropriately, threatening the machine's performance. Ignoring these auditory warnings can bring about more substantial damage and expensive fixings. Acknowledging and addressing uncommon noise patterns is essential for preserving the performance and longevity of a stretch wrapper.

Inconsistent Movie Stress

When movie stress is irregular, it frequently signifies that a stretch wrapper requires repair work. This issue shows up as unevenly wrapped pallets, resulting in inadequate load stability and raised threat of item damage during transportation. Operators might observe that some areas of film are exceedingly tight while others are loose, resulting in inefficient control. In addition, fluctuating tension can create the movie to slide or move during application, compromising the total wrapping procedure. Such disparities might stem from mechanical problems, such as used rollers or malfunctioning stress controls. Dealing with these issues without delay is important to keeping operational performance and making certain that item stability is upheld throughout the shipping procedure. Routine evaluations can help recognize these troubles before they escalate.

Frequent Movie Damage

Frequent movie damage is a clear indicator that a stretch wrapper may require fixing, additional worsening issues related to irregular movie stress. This issue not only interferes with the packaging process but can additionally result in item damage and raised labor expenses. When the movie regularly snaps, it frequently signifies underlying mechanical issues, such as used rollers, improper placement, or inadequate pre-stretch setups. Operators may observe that modifications to tension settings are inadequate, suggesting a demand for professional evaluation. Timely repair service can avoid manufacturing delays and preserve product packaging stability. Normal upkeep checks can help recognize potential issues early, guaranteeing peak efficiency and minimizing the risk of regular film breakage in future operations.

The Advantages of Normal Maintenance

Normal maintenance of stretch wrappers not only enhances their performance yet also prolongs their functional life-span. By consistently evaluating and servicing these machines, companies can ensure peak functionality and stay clear of unanticipated breakdowns. Scheduled maintenance aids in identifying prospective issues prior to they intensify, reducing the risk of manufacturing delays.Moreover, well-maintained stretch wrappers offer constant covering top quality, which is essential for protecting items during transportation and storage (stretch wrapper repair). This uniformity causes fewer product damages and boosted customer satisfaction.Additionally, routine maintenance can boost power effectiveness, resulting in lower operational expenses in time. It promotes a more secure working setting by decreasing the opportunities of mishaps brought on by malfunctioning tools. Generally, positive maintenance techniques add to a smoother operations, enabling companies to focus on their core operations with self-confidence in their devices's dependability

Cost Effects of Neglecting Fixes

Ignoring repairs on stretch wrappers can bring about considerable economic repercussions for companies, as unaddressed issues commonly rise right into much more severe troubles. When operational inefficiencies arise, firms may experience raised downtime, leading to shed productivity and revenue. Furthermore, frequent failures can necessitate emergency fixings, which are typically more pricey than regular maintenance.Moreover, the expense of damaged products as a result of inadequate covering can collect quickly, bring about greater waste and replacement expenses. Substandard covering can likewise affect delivering efficiency and increase the danger of item returns, further stressing financial resources.In the long-term, constantly overlooking repair services can diminish the life expectancy of devices, requiring costly replacements sooner than expected. Inevitably, the cumulative result of these factors can significantly influence a firm's bottom line, highlighting the importance of prompt and aggressive maintenance strategies for stretch wrappers.

Best Practices for Stretch Wrapper Maintenance

Carrying out reliable upkeep methods for stretch wrappers can substantially boost their efficiency and longevity. Regular examination is important; operators ought to look for damage on parts like belts, rollers, and movie dispensers. Cleaning the machine frequently aids protect against particles build-up, which can result in breakdowns. Lubrication of moving parts ought to follow supplier standards to guarantee smooth operation.Additionally, keeping correct stress and alignment of the movie is necessary to achieve the most effective covering top quality. Operators ought to likewise keep detailed maintenance logs to track any kind of concerns and repair services, permitting prompt treatments. Training team on appropriate operation and maintenance treatments can minimize the danger of human error and prolong tools life. Scheduling routine expert evaluations can recognize prospective problems prior to they rise, safeguarding constant performance. By complying with browse around this site these best techniques, organizations can reduce downtime and boost the dependability of their stretch wrappers.

Picking the Right Repair Solution for Your Stretch Wrapper

Choosing the ideal repair service for a stretch wrapper is an important action in maintaining operational effectiveness and lessening downtime. Businesses must prioritize services that concentrate on stretch wrapper repair services, as these professionals have the needed know-how and experience to diagnose and settle issues effectively.It is suggested to evaluate prospective repair service services based on their track record, customer evaluations, and action times. A trusted see page solution must offer timely support and have a proven track document of effective repair services. In addition, organizations need to ask regarding the schedule of substitute components and whether the service uses OEM parts to assure compatibility and longevity.Furthermore, recognizing the warranty and solution contracts can provide insight right into the degree of assistance offered post-repair. By very carefully picking a proficient repair solution, businesses can guarantee their stretch wrappers stay operational, consequently boosting performance and maintaining a smooth process.

Frequently Asked Inquiries

Just how Frequently Should I Schedule Upkeep for My Stretch Wrapper?

Maintenance for a stretch wrapper should be arranged routinely, generally every 3 to six months, depending upon use - stretch wrapper repair. This assures peak performance, minimizes downtime, and lengthens the devices's life-span, eventually enhancing general operational effectiveness

Can I Perform Standard Repair Services on My Stretch Wrapper Myself?

Basic repairs on a stretch wrapper might be feasible for people with mechanical understanding. Caution is suggested; incorrect fixings can lead to further damage and security dangers, stressing the relevance of specialist assistance when required.

What Are the Service Warranty Effects of Do It Yourself Services?

The guarantee ramifications of DIY repair work can be significant. Producers usually invalidate guarantees if unapproved repair services are attempted, causing potential financial loss and added prices for professional service, stressing the relevance of adhering to guarantee standards.

Just How Do Environmental Aspects Impact Stretch Wrapper Performance?

Ecological aspects such as moisture, temperature level, and dirt can substantially influence stretch wrapper performance. Extreme problems may influence material integrity, machine performance, and total efficiency, potentially resulting in increased wear and lowered functional lifespan otherwise appropriately handled.

What Spare Parts Should I Stock for My Stretch Wrapper?

To guarantee peak performance, it is suggested to keep important extra parts for a stretch wrapper, including rollers, belts, movie stress springs, sensors, and control panel, minimizing and promoting punctual repairs downtime in operations. Timely upkeep and repair work of stretch wrappers are essential for service performance. When movie tension is inconsistent, it usually symbolizes that a stretch wrapper requires repair service. Constant film breakage navigate here is a clear indicator that a stretch wrapper might need fixing, more intensifying issues associated to inconsistent film tension. Overlooking repair services on stretch wrappers can lead to considerable monetary repercussions for organizations, as unaddressed issues commonly rise into extra extreme troubles. Businesses need to focus on solutions that specialize in stretch wrapper repair work, as these professionals possess the required knowledge and experience to detect and deal with issues effectively.It is a good idea to evaluate possible repair service services based on their credibility, customer testimonials, and reaction times.